The Dutch Door (a pair of half doors) was common in the Netherlands in the seventeenth century and appears in Dutch paintings of the period. They were also commonly found in the Dutch cultural areas of New York and New Jersey before the American Revolution. The initial purpose of this door was to keep animals out of farmhouses, or keep children inside, while allowing light and air to filter through the open top. They were also an intregal part of trains, for the conductors and passengers safety

|

Woman at a Dutch Door, 1645,

by Samuel van Hoogstraten

|

|

| Woman at a Mendocino Dutch Door |

CLICK ON ANY IMAGE TO ENLARGE

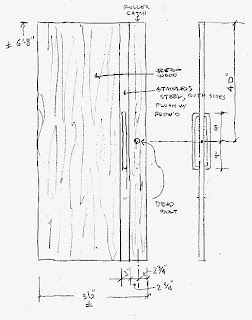

The Dutch Door offers a certain freedom to a room or home. It lets the outside in and keeps the outside out. Most Dutch Doors open inward and are almost a secure as a single door if they are connected together mechanicaly. My clients love the beauty of wood and the beauty of their surroundings. I believe they want to bring the environs into their home, kitchen, or studio, as much as possible.

|

| Here is a view from the inside what a nice view |

|

| Here is a close-up of the styles of hardware we used. Both halves lock with keys. |

The "excitement" at Mendocino Doors is that the client gets to design his or her Dutch Door. Some folk wish to have multi-light panes or single lite arched-top. It is your door and you get to help me design it. You can design simple panels, art glass, or even a dentil shelf. The Dentil Shelf is attached to the Dentil Posts with stainless steel screws and covered with rosewood pins. How would you want your Dutch Door?

|

| The Dentil Shelf |

|

| The panels are Curly and Burl Redwood |

|

| The "half-lap" joint has weatherstripping |

Soooooo ..........if you might ever want a Dutch Door, just give me a call or drop me a note and we'll design your door together, and you can make your dreams come true.

|

| Here is a Dutch Door we just finished |

You can go to MendocinoDoors.com and go to The Magnolia Hill Dutch Door to see some more pictures of the construction and completion of this beautiful door.

Thanks for taking your time to listen to me ramble !